More information:

Description

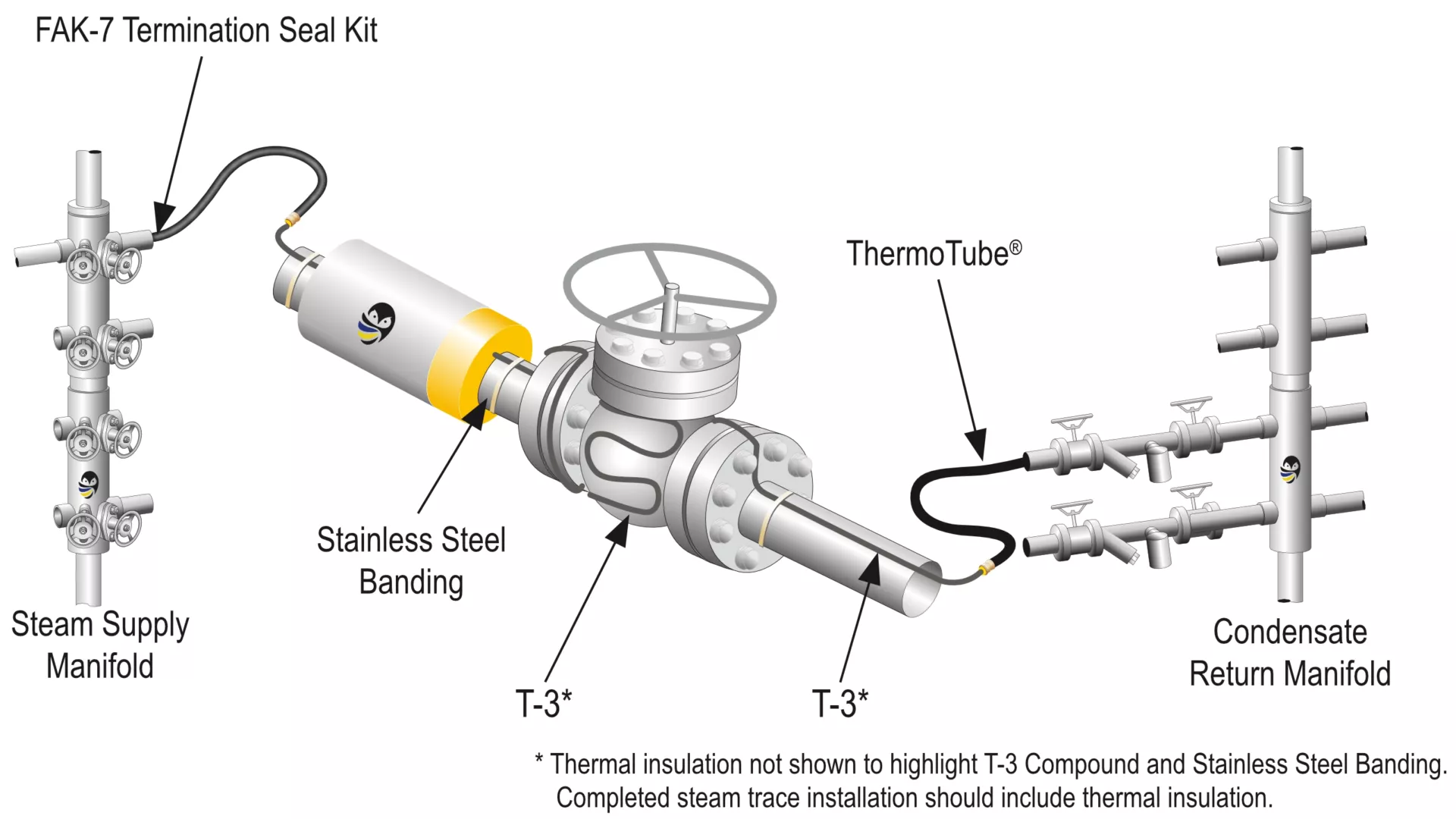

Thermon’s T-3 heat transfer compound establishes an effective thermal connection between a steam or electric heater and process pipes or equipment. Using a single Thermonized steam tracer with Thermon’s heat transfer compound proves more cost-effective than employing a contoured clamp-on jacket and delivers performance equivalent to three (or more) bare tracers.

Typically employed for applications with maximum exposure temperatures of 454°C, T-3 enhances efficiency. For streamlined installation and reduced waste, consider using Thermon’s ChannelTrace system featuring TFK channels. The ChannelTrace system offers protection before the installation of thermal insulation and requires no special curing procedure for the T-3 heat transfer compound.

FEATURES

- Significantly enhance heat transfer rates compared to bare tracing, reducing the need for numerous tracers and steam traps

- Decreased reliance on steam tracers results in quicker installation times, with ChannelTrace eliminating unnecessary waste

- Easy cleanup with water-soluble properties

- No special curing procedure needed for tracing under TFK channels

Product variants

| SKU | P/N | Item | Volume |

| 2029-001 | 16080 | STANDARD T-3-1 | 3.79 liter |

| 2029-002 | 16082 | STANDARD T-3-5 | 18.93 liter |

THERMON-DS-T-3-TSP0015U-0321.PDF

Datasheet

Additional information

| Packaging | T-3-1 = 3.79-liter pail |

|---|---|

| Max. exposure temperature (ASTM C447) | 454°C |

| Min. exposure temperature | -196°C |

| Min. installation temperature | 0°C |

| Heat transfer coefficient, Ut, tracer to pipe wall | 114-227 W/m² • °C |

| Nominal electrical resistivity | 0.86 ohms-cm |

| Shelf life (unopened) | 18 months |

| Bond Strength (ASTM D1002) | > 1380 kPa |

| Water Soluble Chlorides (ASTM C1218) | < 100 ppm |

| Water-soluble | Yes |